Bedload monitoring system

developed in FIThydro

Contents

Quick summary

Developed by: VAW, ETH Zurich, Switzerland; Test Case partner: Limmatkraftwerke AG, Baden, Switzerland

Date: February 2019

Type: Device

Introduction

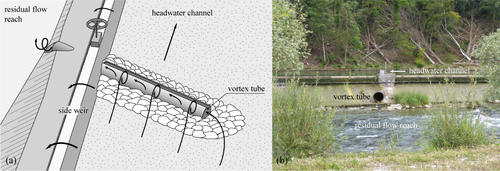

An indirect Bedload Monitoring System (BMS) is developed for bedload transport monitoring in the vortex tube system installed in the headwater channel of the FIThydro case study hydropower plant (HPP) Schiffmühle. The BMS allows the quantitative assessment of bedload transport in rivers, torrents and hydraulic sediment diversion structures. The measurements support the evaluation of bedload continuity across hydropower plants or other hydraulic structures.

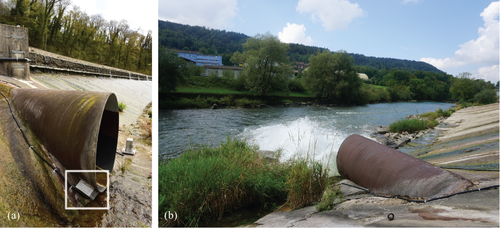

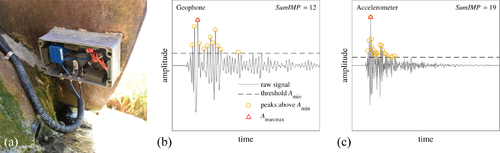

The BMS consists of two passive acoustic sensors, i.e. a geophone (GS-20DX manufactured by Geospace Technologies, Houston TX, USA) and an accelerometer (ICP352C03 manufactured by PCB Piezoelectronics, Depew NY, USA), mounted on an impact plate in a watertight housing (Figure 1a). These sensors do not directly measure bedload transport, but register the vibration signals of the impact plate, i.e. oscillations induced by the impingement of passing bedload particles. In the case study HPP, the impact plate is the steel wall of the vortex tube (Figure 1a). The vibration signal output of both sensors is a voltage that is sampled at a frequency of 51.2 kHz. The raw signals are then transmitted and further processed (Figure 1b, c).

The BMS presented here is similar to the Swiss Plate Geophone System (SPGS) (Rickenmann et al. 2012), but includes an additional accelerometer sensor to expand the range of frequencies and hence the potentially detectable particle sizes compared to the SPGS.

The maximum amplitude recorded during a bedload transport event can be related to the maximum grain diameter. Additionally, the sum of impulse counts above a certain amplitude threshold can be related to the transported bedload volume. Both relations are BMS setup- and site-dependent and therefore, a calibration is required to correlate the recorded impact signals to known bedload transport rates, often obtained from traditional bedload sampling (Rickenmann et al. 2012). If possible, a calibration in a laboratory flume as well as in the field setting is recommended (Gray et al. 2010, Rickenmann et al. 2014, Wyss et al. 2016a, Wyss et al. 2016b, Albayrak et al. 2017).

Application

Within the scope of FIThydro, a BMS consisting of a geophone and accelerometer was installed on the vortex tube at HPP Schiffmühle, which diverts bedload from the headwater channel to the residual flow reach. The vortex tube consists of a steel tube embedded in the side weir, connecting the two parallel channels (Figure 2). A gate valve is positioned in the side weir, which opens automatically when a predefined discharge is exceeded. The opening of the valve automatically triggers the BMS measurements.

In contrast to the SPGS, the steel tube is used as an impact plate for the BMS and the sensors are mounted directly onto the outside of the steel tube (Figure 3). Therefore, laboratory calibration was not easily possible. Instead, the system was calibrated in the field, by repeatedly dumping sediment samples of known grain size distribution and volume upstream of the vortex tube and subsequently flushing them to the residual flow reach. In addition, drop tests with single grains were performed when the vortex tube was not in operation. The single grain signals help to analyze the influence of grain size, grain form, drop height, and drop location on the amplitude and frequency signals.

The first results of the presented BMS are promising, but the data analysis will be further refined and extended. Furthermore, a larger number of recorded flood events is necessary to check the plausibility of the results obtained so far. Overall, it is demonstrated that the measurement principle of the SPGS can be extended to non-standardized impact plates, like steel vortex tubes, and to the use of an additional accelerometer sensor, given that appropriate calibration measures are taken.

Relevant mitigation measures and test cases

Other information

The total costs for the geophone and accelerometer sensors amount to approx. 885-1'330 €. The costs for the field computer, the analog-digital-converter, and the 3G modem are approx. 5'300-6'200 €. Additional costs must be considered for the installation, data transmission and calibration, depending on the site conditions and set-up.

Relevant literature

- Albayrak, I., Müller-Hagmann, M., Boes, R.M. (2017). Calibration of Swiss Plate Geophone System for bedload monitoring in a sediment bypass tunnel. In Proc. 2nd Intl. Workshop on Sediment Bypass Tunnels (Sumi, T., ed.), paper FP16, Kyoto University, Kyoto, Japan

- Gray, J.R., Laronne, J.B., Marr, J.D.G. (2010). Bedload-surrogate Monitoring Technologies, US Geological Survey Scientific Investigations Report 2010-5091. US Geological Survey: Reston VA.

- Rickenmann, D., Turowski, J.M., Fritschi, B., Klaiber, A., Ludwig, A. (2012). Bedload transport measurements at the Erlenbach stream with geophones and automated basket samplers. Earth Surface Processes and Landforms, 37, 1000-1011.

- Rickenmann, D., Turowski, J.M., Fritschi, B., Wyss, C., Laronne, J., Barzilai, R., Reid, I., Kreisler, A., Aigner, J., Seitz, H., Habersack, H. (2014). Bedload transport measurements with impact plate geophones: comparison of sensor calibration in different gravel-bed streams. Earth Surface Processes and Landforms, 39, 928-942.

- Wyss, C.R., Rickenmann, D., Fritschi, B., Turowski, J.M, Weitbrecht, V., Boes, R.M. (2016a). Laboratory flume experiments with the Swiss plate geophone bed load monitoring system: 1. Impulse counts and particle size identification. Water Resources Research, 52, 7744-7759.

- Wyss, C.R., Rickenmann, D., Fritschi, B., Turowski, J.M, Weitbrecht, V., Boes, R.M. (2016b). Laboratory flume experiments with the Swiss plate geophone bed load monitoring system: 2. Application to field sites with direct bed load samples. Water Resources Research, 52, 7760-7778.