Difference between revisions of "FLOW-3D"

Bendikhansen (talk | contribs) m (Text replacement - "[::Category" to "[:Category") |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

=Quick summary= | =Quick summary= | ||

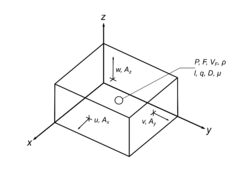

[[file:flow3d_xyz.png|thumb|250px|Figure 1: Location of variables in FLOW-3D computational mesh (source: FLOW-3D)]] | [[file:flow3d_xyz.png|thumb|250px|Figure 1: Location of variables in FLOW-3D computational mesh (source: FLOW-3D)]] | ||

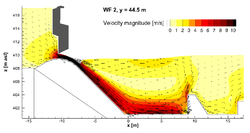

| − | [[file:flow3d_hpp.png|thumb|250px|Figure 2 | + | [[file:flow3d_hpp.png|thumb|250px|Figure 2: Example of a river power plant geometry set up for FLOW-3D (source: VAW)]] |

[[file:flow3d_banwil1.png|thumb|250px|Figure 3: Example visualization of FLOW-3D simulation results for the case study HPP Banwil showing flow velocities and streamlines at a potential location for fish guidance structures (source: VAW)]] | [[file:flow3d_banwil1.png|thumb|250px|Figure 3: Example visualization of FLOW-3D simulation results for the case study HPP Banwil showing flow velocities and streamlines at a potential location for fish guidance structures (source: VAW)]] | ||

| − | [[file:flow3d_banwil2.png|thumb|250px|Figure | + | [[file:flow3d_banwil2.png|thumb|250px|Figure 4: Example visualization of FLOW-3D simulation results for the case study HPP Banwil showing flow velocities and streamlines during spillway operations (source: VAW)]] |

Developed by: Flow Science, Inc (Santa Fe, New Mexico, USA) | Developed by: Flow Science, Inc (Santa Fe, New Mexico, USA) | ||

| Line 12: | Line 12: | ||

Type: [[:Category:Tools|Tool]] | Type: [[:Category:Tools|Tool]] | ||

| − | |||

=Introduction= | =Introduction= | ||

| Line 25: | Line 24: | ||

=Application= | =Application= | ||

FLOW-3D supports Windows as well as Linux platforms and includes a powerful graphical user interface (GUI) which supports the user during the model setup and simulation process. | FLOW-3D supports Windows as well as Linux platforms and includes a powerful graphical user interface (GUI) which supports the user during the model setup and simulation process. | ||

| − | 3D solid structures are imported into the GUI in the form of stereolithographic files (STL). Figure 2 shows the exemplary geometry set-up of the FIThydro case study hydropower plant (HPP) Bannwil in Canton Bern, Switzerland for FLOW-3D. Definition of mesh blocks and mesh resolution, as well as boundary and initial conditions, can | + | 3D solid structures are imported into the GUI in the form of stereolithographic files (STL). Figure 2 shows the exemplary geometry set-up of the FIThydro case study hydropower plant (HPP) Bannwil in Canton Bern, Switzerland for FLOW-3D. Definition of mesh blocks and mesh resolution, as well as boundary and initial conditions, can be done in the GUI. The use of multiple mesh blocks allows for local refinement at areas of interest. Small obstacles, complex geometries and thin channels that are small compared to the overall domain size can be accurately resolved using so called conforming mesh blocks. In FLOW-3D “conforming mesh” means, that the transition between solid and void or solid and fluid is resolved with a nested finer mesh within a defined overlap length compared to the surrounding block. |

The software license includes the post-processing tool FlowSight, designed to deliver sophisticated visualizations of FLOW-3D results. Arbitrary 2D clips along spline pathways, 3D clips and transparencies, volume rendering, advanced data time series plotting and calculators, streamline and vector plots are available in FlowSight (Figure 3 and 4). Alternatively, the result files can be visualized using other free (e.g. ParaView) or commercial (e.g. Tecplot) CFD visualization software. | The software license includes the post-processing tool FlowSight, designed to deliver sophisticated visualizations of FLOW-3D results. Arbitrary 2D clips along spline pathways, 3D clips and transparencies, volume rendering, advanced data time series plotting and calculators, streamline and vector plots are available in FlowSight (Figure 3 and 4). Alternatively, the result files can be visualized using other free (e.g. ParaView) or commercial (e.g. Tecplot) CFD visualization software. | ||

| + | |||

| + | =Relevant mitigation measures and test cases= | ||

| + | {{Suitable measures for FLOW-3D}} | ||

=Other information= | =Other information= | ||

Latest revision as of 08:54, 18 September 2020

Contents

Quick summary

Developed by: Flow Science, Inc (Santa Fe, New Mexico, USA)

Date: 2016 (FLOW-3D release v11.2)

Type: Tool

Introduction

FLOW-3D is a commercial CFD simulation software that focusses on free-surface flows in a wide range of industrial applications and physical processes. The software solves the Navier-Stokes equations that mathematically describe the 3D motion of fluids. The domain is subdivided into several mesh blocks containing rectangular grid cells (structured mesh). Fluid velocities and pressures are located at staggered mesh locations as shown for a typical grid cell in Figure 1.

The numerical model involves the following variables: velocities (u,v,w) and fractional areas (A) at the centers of cell-faces, pressures (P), fluid fractions (F), fractional volumes (VF), densities (ρ), internal energy (I), turbulence quantities for energy (q), dissipation (D) and viscosity (μ) are located at cell centres.

In FLOW-3D, one or two equation turbulence models (e.g. k-ε model), as well as more computationally expensive large eddy simulation (LES) methods, are available for turbulence modelling. Wall boundaries and other solid geometrical structures like power plant facilities are embedded in the orthogonal mesh by the so called FAVORTM method. This algorithm defines the fractional face areas and fractional volumes of the cells that are open to fluid flow. Thus, the mesh does not have to be fit around complex geometry during the pre-processing. In order to properly capture the free-surface dynamics, the Volume of Fluid (VOF) method is applied in FLOW-3D.

Application

FLOW-3D supports Windows as well as Linux platforms and includes a powerful graphical user interface (GUI) which supports the user during the model setup and simulation process. 3D solid structures are imported into the GUI in the form of stereolithographic files (STL). Figure 2 shows the exemplary geometry set-up of the FIThydro case study hydropower plant (HPP) Bannwil in Canton Bern, Switzerland for FLOW-3D. Definition of mesh blocks and mesh resolution, as well as boundary and initial conditions, can be done in the GUI. The use of multiple mesh blocks allows for local refinement at areas of interest. Small obstacles, complex geometries and thin channels that are small compared to the overall domain size can be accurately resolved using so called conforming mesh blocks. In FLOW-3D “conforming mesh” means, that the transition between solid and void or solid and fluid is resolved with a nested finer mesh within a defined overlap length compared to the surrounding block.

The software license includes the post-processing tool FlowSight, designed to deliver sophisticated visualizations of FLOW-3D results. Arbitrary 2D clips along spline pathways, 3D clips and transparencies, volume rendering, advanced data time series plotting and calculators, streamline and vector plots are available in FlowSight (Figure 3 and 4). Alternatively, the result files can be visualized using other free (e.g. ParaView) or commercial (e.g. Tecplot) CFD visualization software.

Relevant mitigation measures and test cases

Other information

In addition to the use on regular Windows and Linux workstations, the High Performance Computing (HPC) version of FLOW-3D is designed to run on distributed memory computer clusters allowing engineers to tackle problems with very large computational domains or long simulation time. For users with limited access to hardware resources, the HPC version is also available on the FLOW-3D CLOUD computing service.

General advantages & disadvantages of the tool (no claim for completeness)

|

Pros |

Cons |

|

Relatively easy to use due to GUI and integrated pre and post-processing |

Commercial software (licenses costs) |

|

Detailed documentation available |

Source code not available |

|

Access to HPC services via Cloud |

Cartesian gird |

Relevant literature

- Kammerer, S., Lutz, N., Vetsch, D., Kriewitz, K. R., Früh, H. (2018). Beurteilung der Unterhaltspflicht eines Regulierwehrs mit Kraftwerk mittels 3D Simulationen, 19. Wasserbausymposium Graz 2018, *Graz, Austria, pp.237-244, Graz: Verlag der Technischen Universität Graz, September 18-20.

- Duguay, J., Lacey, R.W.J., Gaucher, J. (2017). A case study of a pool and weir fishway modeled with OpenFOAM and FLOW-3D. Ecological Engineering. 103. 31-42. doi: 10.1016/j.ecoleng.2017.01.042.

- Duguay, J., Lacey, R.W.J. (2014), Use of Numerical Hydraulic Modeling to Improve Fish Passage at Perched Culverts. Canadian Journal of Civil Engineering, 2016, 43(2): 173-181. dx.doi.org/10.1139/cjce-2014-043

Contact information

FLOW-3D webpage: https://www.flow3d.com/

Water & Environmental applications: https://www.flow3d.com/industries/water-environmental/