Other types of fine screens

Contents

Introduction

Several types of fine screen have been developed such as:

- Eicher screens and MIS screens, inclined at a shallow angle to the flow direction inside a turbine water intake, pipe, or penstock to divert the fish towards a bypass

- Angled rotating, self-cleaning drum screens.

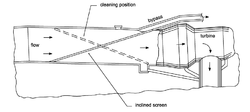

Eicher screens are high-speed conduits used for diverting fish at intakes. An axis in the center of the grid makes it possible to tilt the grid for cleaning. EPRI (1992) reports> 90% survival for Coho, Chinook and Steelhead smolt and fry at speeds of 2 m/s at the rack in a power station with 147-170 m3/s intake discharge. The screen had a dimension of 14.2 x 7.2 m (L x B), an angle of 16 ° and 0.9-3.2 mm gap width.

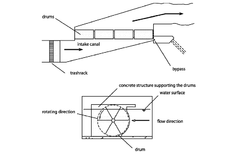

Rotary screens (Larinier, et al., 2002). Rotating, self-cleaning drum screens are commonly used in irrigation channel intakes in the USA ( (Nietzel, et al., 1990), (Rainey, 1990)). These screens, which are generally powered by an electric motor on larger installations, provide a very effective solution to the problem of diverting fish into shallow channels (Figure 2). Existing drum dimensions can vary from 0.45 m in diameter by 0.90 m long up to 6 m in diameter by 7 m long (ASCE, 1995). They are installed across a channel at a specified angle (around 26°) to guide fish into a bypass. The mesh is made either of stainless steel or galvanised wire. The use of drum screens is limited to sites where water level variations are very limited since the screens must be 70 to 80% submerged to remain effective. Experience shows that drum screens can be highly effective in guiding salmon fry and juveniles to bypasses with very little damage to the fish.

Methods, tools, and devices

During planning

Planning of fine-mesh screen and bypass systems require a comprehensive study on fish behaviour to assess when and where fish move on their downstream migration. This can be conducted by telemetry experiments or visual observations with video or sonar technology. River hydraulics at the intake must be modelled by 2D or 3D CFD software if needed. The physical installations of the screen and bypass corridor(s) must be planned according to the power plant geometry and construction works must be adapted to physical forces and the hydropower scheme.

During implementation

Construction of fine-mesh screen requires heavy lifting equipment and both fixing and placing of the structure needs to be done when the hydropower plant is brought to full stop. Installation of screens and a bypass system requires a suite of skilled labour on civil works.

During operation

An Eicher screen requires protective trash-racks to be placed upstream of them to prevent large-sized debris from entering the system (Winchell, et al., 1993).

The Rotating, self-cleaning drum screen is as it name implies self-cleaning and doesn’t need a cleaning machine.

Relevant MTDs and test cases

Classification table

| Classification | Selection |

|---|---|

| Fish species for the measure | All |

| Does the measure require loss of power production | Operational (requires flow release outside turbine) |

| - | |

| - | |

| Recurrence of maintenance | Weekly |

| Which life-stage of fish is measure aimed at | - |

| - | |

| - | |

| Movements of migration of fish | |

| Which physical parameter is addressed | N/A |

| - | |

| - | |

| - | |

| - | |

| - | |

| - | |

| - | |

| Hydropower type the measure is suitable for | Plant in dam |

| Plant with bypass section | |

| Dam height (m) the measure is suitable for | All |

| Section in the regulated system measure is designed for | In dam/power plant |

| - | |

| - | |

| - | |

| River type implemented | Steep gradient (up to 0.4 %) |

| Fairly steep with rocks, boulders (from 0.4 to 0.05 %) | |

| Slow flowing, lowland, sandy (less than 0.05 %) | |

| Level of certainty in effect | Very certain |

| Technology readiness level | TRL 8: system complete and qualified |

| Cost of solution | See cost table |

Relevant literature

- Larinier, M. and Travade, F. 2002. Downstream migration: problems and facilities. Bulletin Francais De La Peche Et De La Pisciculture 364: 181-207

- Nietzel, D.A., Clunet, T.J. et Abernethy, C.S. 1990. Evaluation of rotary drum screens used to project juvenile salmonids in the Yakima river basin, Washington, USA. s.l. : Proc. Int. Symp. on fishways, Gifu, Japan, 1990. pp. 523-529.

- Rainey, W.S. 1990. Cylindrical drum screeens design for juvenile fish protection at two large diversions. s.l. : Prot. Int. Symp. on fishways, Gifu, Japan, 1990. pp. 143-150.

- ASCE. 1995. Fish passage and protection. Guidelines for Design of intakes for hydroelectrics plants. New York, N.Y. : American Society of Civil Engineering, 1995, pp. 469-499

- Winchell, F.C., Taft, E.P. et Cook, T. 1993. EPRI's evaluation of the Elwa dam Eicher Screen and subsequent design changes and hydraulic tests. Portland, Oregon, USA : Proc. Symp. American Fisheries Cosiety, Fish passage policy and technology, 1993. pp. 189-196.